History of Quality in Construction

Published January 9, 2015

Figure 1: China's Quality Journey

Figure 1: China's Quality Journey

A Brief History of Quality in Construction

While many would like to think that quality in construction started in the recent past (1970’s and 80’s), in reality, our current quality processes and approaches are the culmination of several thousands of years of development and implementation. In fact, back in 700 BC, China had a comprehensive set of standards, inspections, and training to provide high quality parts repeatability.

In looking at the history of quality[1], there is a logical development across the globe, starting in China and progressing to Greece, Rome, and eventually Northern Europe.

China

A key foundation to the Chinese Quality Systems was the fact that they were ruled under a dynasty structure (central power) from around 2000 BC to 1911. It is the bureaucracy of the dynasty structure that led to their quality programs throughout their economy. Several key points with respect to development of construction quality are shown in Figure 1.

While many would like to think that quality in construction started in the recent past (1970’s and 80’s), in reality, our current quality processes and approaches are the culmination of several thousands of years of development and implementation. In fact, back in 700 BC, China had a comprehensive set of standards, inspections, and training to provide high quality parts repeatability.

In looking at the history of quality[1], there is a logical development across the globe, starting in China and progressing to Greece, Rome, and eventually Northern Europe.

China

A key foundation to the Chinese Quality Systems was the fact that they were ruled under a dynasty structure (central power) from around 2000 BC to 1911. It is the bureaucracy of the dynasty structure that led to their quality programs throughout their economy. Several key points with respect to development of construction quality are shown in Figure 1.

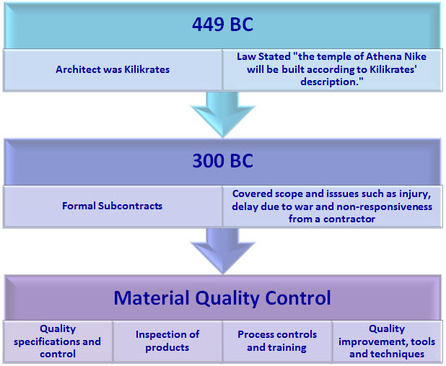

Figure 2: Greek's Focus on Law

Figure 2: Greek's Focus on Law

Additional items such as planning for production (efficiency), division of labor into workshops, recruiting and training craftsmen, control of cost, and examination and custody permeate throughout the creation and implementation of quality in China.

Greece

The Greek approach to quality was that the architect was responsible for the design and construction of the project, with a heavy reliance on formal laws and contracts, as highlighted in Figure 2.

Rome

In ancient Rome power was highly centralized and in order to maintain the prestige, the ruling class had to offer acceptable living conditions (minimum standard) for the general population in order to obtain consent of the populations and thus legitimize their own positions.

A simple way to describe this was “panem et circenses” or simply bread and circuses – by giving the population food and entertainment, their basic needs and organized displays of urban opulence and mass entertainment. This also required continued growth (conquer others) to fuel the central growth and needs (a whole lot of slaves).

Northern Europe

Throughout northern Europe, the use of guilds was the primary means of establishing and maintaining quality. Around 1000 AD there is evidence of “marks” being made by stone masons to identify who did what work. By 1400 AD, this led to people trusting “sealed” materials in bundles and just purchasing “as is” as they trusted the quality received.

How History of Quality Applied Today The value of learning and understanding the history of quality with respect to construction provides a sound foundation to all current and future quality programs in construction. Primarily, recognizing the core principles that have been established through practice over the past millennium enables us to maintain our focus on the fundamentals regardless of whatever we call our program – put another way, the basics do not change, they only get better through application and culture.

With respect to current state-of-the-art construction quality program, they are similar to the examples of quality evolution from ancient history, in that they have continued to evolve and adapt from within and adopt from other industries (manufacturing), ranging from total quality management (TQM) to quality assurance/quality control (QA/QC).

See the Language of Construction Quality for a review of modern construction quality programs.

Footnote:

Greece

The Greek approach to quality was that the architect was responsible for the design and construction of the project, with a heavy reliance on formal laws and contracts, as highlighted in Figure 2.

Rome

In ancient Rome power was highly centralized and in order to maintain the prestige, the ruling class had to offer acceptable living conditions (minimum standard) for the general population in order to obtain consent of the populations and thus legitimize their own positions.

A simple way to describe this was “panem et circenses” or simply bread and circuses – by giving the population food and entertainment, their basic needs and organized displays of urban opulence and mass entertainment. This also required continued growth (conquer others) to fuel the central growth and needs (a whole lot of slaves).

- Rome was an empire of builders requiring extensive standardization, master planning and execution, and the use of measuring instruments and methods.

- 300 BC – there are still parts of the original Appian Way in existence today – this is part of the Roman Road. Put simply, the Romans had created a paving system back in 300 BC. In addition, this was the same time period of constructing massive aqueducts to assure high quality water access to the people in cities.

- 105 BC – a decree that specified contractual terms of delivery, payment and assessment of structural integrity for a building project.

- Quality was based on a distribution of responsibility – you reported and were responsible to your immediate supervisor – a very hierarchical structure.

- 500 AD – Romans were manufacturing bricks for use in construction. This included the use of brick stamps and contracts to trace responsibility.

- 100 AD – the use of concrete to create huge vaults and domes.

- Throughout history, the Romans utilized a building yard approach to organizing construction into trades that sequenced work from one to the other – e.g., first the wall frame, then plaster, and finally whitewash.

Northern Europe

Throughout northern Europe, the use of guilds was the primary means of establishing and maintaining quality. Around 1000 AD there is evidence of “marks” being made by stone masons to identify who did what work. By 1400 AD, this led to people trusting “sealed” materials in bundles and just purchasing “as is” as they trusted the quality received.

- 1000-1800 – the Guilds are the original unions where it was illegal to practice a trade unless you belonged to the Guild. This was strictly enforced and provided the apprenticeship we think of today in unions. The marks they utilized typically included crests of the guild and the city of origin.

- 1300 – there is evidence in the textile industry of well-defined regulations for quality assurance.

- 1380 – watermarks on paper were started to define quality and give assurance of quality to the purchaser.

- 1880 – “made in XXX” and trademarks formalized into law.

How History of Quality Applied Today The value of learning and understanding the history of quality with respect to construction provides a sound foundation to all current and future quality programs in construction. Primarily, recognizing the core principles that have been established through practice over the past millennium enables us to maintain our focus on the fundamentals regardless of whatever we call our program – put another way, the basics do not change, they only get better through application and culture.

With respect to current state-of-the-art construction quality program, they are similar to the examples of quality evolution from ancient history, in that they have continued to evolve and adapt from within and adopt from other industries (manufacturing), ranging from total quality management (TQM) to quality assurance/quality control (QA/QC).

See the Language of Construction Quality for a review of modern construction quality programs.

Footnote:

- Juran, J.M., A History of Managing for Quality, ASQC Quality Press, Milwaukee, WI, 1995.

The Construction Quality Executives Council (CQEC) is an industry organization composed of Quality Leaders from design and construction firms with formal Quality Programs. The goal of the CQEC is to advance the art and science of quality in the built environment through publications, education and research. The information and views expressed is that of the CQEC and not that of the member’s company. This document is copyrighted (2015©) and the CQEC grants permission to reproduce and distribute as long as credit to the source document and CQEC is maintained.